Madhusudanan N.

PhD student

Centre for Product Design and Manufacturing, Indian Institute of Science, Bengaluru

The aircraft industry consists of a considerable portion of work that is manually performed, and hence the knowledge of experts plays an important role. Knowledge is a useful asset to any modern day manufacturing organisation. Its reuse is gaining impetus in recent times. Even then, some expert knowledge that could be useful is not available across different phases of the product lifecycle. This project aims to reuse expert knowledge from manufacturing and assembly in the planning and implementation stage. It is expected that this will help to prevent potential issues during assembly. This knowledge re-use is intended for a smart manufacturing system that combines this knowledge with data. Documents that contain such expert knowledge of issues are the source.

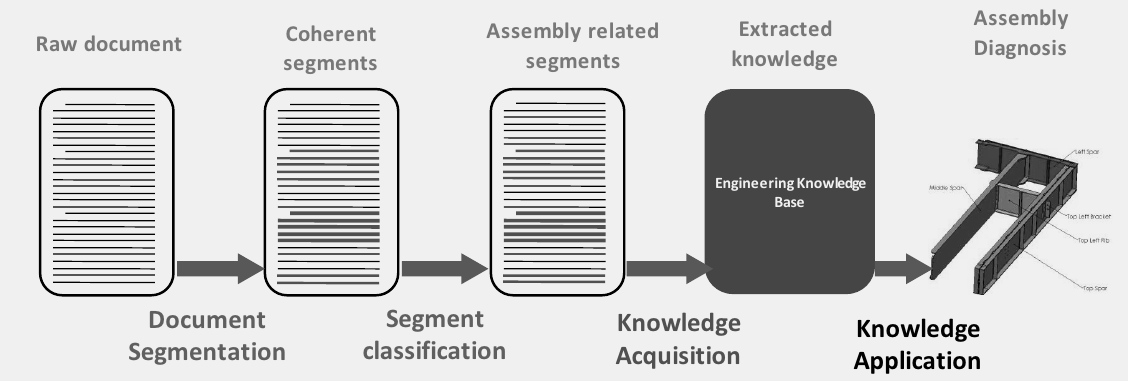

A method is proposed to acquire such knowledge – it has three parts: segregation of relevant text, acquisition of issues, causes and parameters, and realising context of knowledge. The segregation of relevant text identifies coherent segments and classifies them as relevant and irrelevant segments. An understanding based method treats documents as a discourse, and attempts to measure topic changes by looking at the relatedness between the discourse entities. A measure for calculating similarity between sentences has been developed and has been implemented using NLP tools such Python NLTK.

For the acquisition of diagnostic knowledge, the parts of text containing issues are first identified, using Sentiment Analysis. A strategy for finding the causes of issues that combines text patterns and sentiment has also been developed. Relations and parameters that form the cause are dissected to done to reconstruct the rules for the knowledge base so that the violation of the constraint can be tested when applying the knowledge. A hybrid method of using both text patterns and dependency parse of the cause text has been proposed.

Methods have also been proposed for capturing the context during acquisition and using it during application. Context containers that make use of proximity of words to five assemblability factors are used to capture the context. An assembly situation model that combines product and process information to model the application situation is proposed to be used at the application stage. The implementation and evaluation of this is linked to the development of the smart manufacturing system.

Overview of the Knowledge Acquisition Procedure