Product Developed

Dialysis Chair

During dialysis the patients need to sit, recline, sleep and assume Trendelenburg positions without assistance. The chair developed employed an innovative coupler-driven mechanism that uses only one linear actuator to change of postures through a hand-held control which can also be integrated with the arm rest. The leg-rest and back-rest employs a novel mechanism to avoid the uncomfortable sliding on backrest that occurs due to large change in angles. The motion of the chair is jerk-less and noiseless as required for medical applications.

The earlier 2-motor version and the above new substantially improved single motor version of the design are patent-pending. Negotiations for technology licencing to a Hyderabad based company, MegnaTek, is in progress.

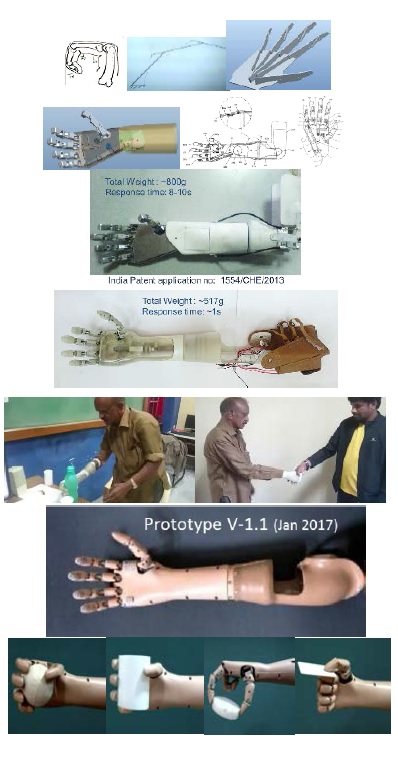

PURAK: Transradial Prosthetic Arm

Loss of an arm due to accidents or disease limits a person’s capability. Consequent socio-economic impact is highly unfavourable. In developing countries functional prosthesis of upper-limb is unaffordable. PURAK was designed to provide functionality with affordability. The work was awarded over 1M GBP funding from Wellcome Trust (UK) for translation and commercial development for India

The device, with fully articulated fingers, employs a single motor driven under-actuated mechanism to adaptively grasp arbitrary shapes, and makes use of the residual limb for the wrist-rotation. It has a unique myo-mechanical control interface; when the stump muscle is stiffened it expands and provides mechanical signal for controlling the motor. Motor stops by relaxing the stump muscle. This is the only prosthesis which lets the amputee feel the grasp force mechanically. It is low cost, light weight (~500gm), responsive (~1sec) and realistic in appearance.

Pan-India market research is completed. Pan-India user trial is due in 2017-18. Design revised twice through continuous user interaction. Pilot trial in India, user trial in

Ultra-Light Tea Harvester

Tea harvesting is a delicate operation as tea is a highly quality sensitive product. Plucking practice is predominantly manual. This device was developed to match the stringent quality and productivity requirements for the tea-estates in India. The design implemented the novel harvester design methodology consisting of identification, isolation, separation and collection stages.

The functional prototype weighs under 1kg vis-à-vis 3.5-7 kg in competition. Its designed productivity is at least double of manual plucking. The device deskills the plucking operation while improving quality and productivity. The projections in front guides the shoots towards a pair of rotating fingers that capture and push them against a small rotating blade to shear.

Cotton Picking by Wrapping

India is a major producer and consumer of cotton in the world. But cotton farming is fragmented making large scale mechanization infeasible. Cotton harvesting is also a delicate and quality sensitive operation. The harvester design methodology consisting of identification, isolation, separation and collection stages have been used in this design also for segregation of design efforts. The novel picker design uses the phenomenon of wrapping of fibrous material around a rotating object. The wrapped cotton is continuously fed into the collection chamber. To solve the dual problem of wrapping and pushing the design employed ingenious mechanisms. Two such devices are patent-pending.

Students working in the project formed a start-up company, Sickle Innovations, which was incubated in IISc and IIM Ahmedabad during which the design, code named Kapas, underwent several field trials and maturation. The company has already received recognition and awards for their innovation. The design approach has been used by the company for developing apple/mango plucking which has received significant market pull.

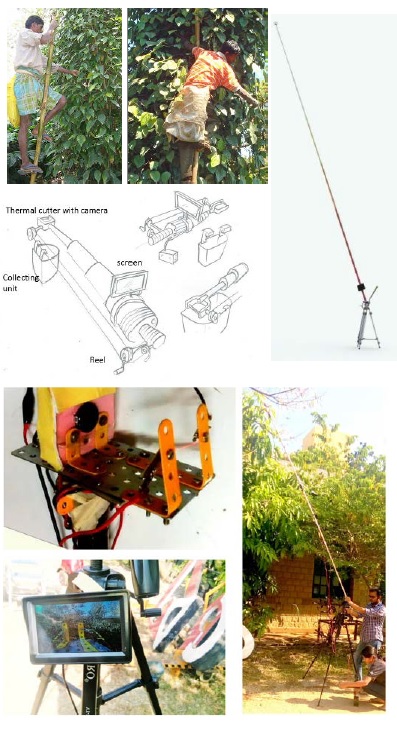

Black-Pepper Harvester

Black-pepper vine grows more than 20m. Traditional methods of harvesting are labour intensive and unsafe. Reach is the primary challenge in its harvesting. The device developed is basically a retractable pole mounted on a tripod; the remote-end of the pole carries a cutter and a camera for viewing the cutting operation through a display mounted at near-end of the pole. Cutting apparatus is a hot wire oscillating along its length. The power for the motor, heater and display are supplied from a 7 AH battery, also mounted on the tripod. The operator does not carry any weight. He also does not look up continuously which is ergonomically advisable. Viewing through the display monitor, he can easily identify and reach the pepper-spikes by manipulating the pole from below, and control the cutting operation too. Cutting takes about one second when the switch on the handle is pressed; it is only then high current is drawn from the battery to heat the cutting wire and move it. The separated spike is harvested through an extendable chute provided. This design is also followed the five stage design methodology for harvesting process, namely identification, isolation, separation, collection and transfer, which was earlier used for designing tea, cotton and apple harvesters, proving the efficacy and versatility of the design methodology developed.